FRANCE: The upcoming plasma-based world’s largest reactor that aims to demonstrate that it is possible to produce commercial electricity from clean energy source fusion is empowering industry globally, including Indian manufacturing.

The 1,250-tonne cryostat base, the first two sections of which have been constructed by conglomerate Larsen & Toubro (L&T), is India’s largest single procurement contribution to the ITER (International Thermonuclear Experimental Reactor) facility that spans over 42 hectares in Saint-Paul-les-Durance, some 35 km north of Aix-en-Provence in south of France.

ITER is a nuclear fusion research and engineering project that will be the world’s largest magnetic confinement plasma physics experiment.

Scientists from all over the world are involved in R&D activities linked to the project and companies are manufacturing millions of components that will be later assembled in Cadarache.

How does it benefit the Indian industry?

“The ITER facility offers industry and the scientific community an unparalleled opportunity to demonstrate its strength, to grow and to learn how to deliver the energy of the future,” ITER Director-General Bernard Bigot told IANS last week in the cryostat workshop where the India-procured component is being assembled and welded.

India is one of the key seven nations aiming to prove that fusion is a viable energy source that will eventually replace fossil fuels and will be complementary with wind, solar, and other renewable energy sources.

Fusion provides the most abundant source of energy in the world.

“Besides cryostat, Indian companies are providing all cooling systems, cryolines, warmlines, neutron seals and many other components. So we can proudly say that Indian industry is doing very well in terms of delivery of equipment for the project,” Bigot, who has been given a second five-year term from March 2020, added.

Besides L&T Heavy Engineering and L&T Construction, many public and private sector companies like INOX India Ltd, Engineers India Ltd, Tata Consultancy Services, Avsarala Technologies as well as firms such as Kirloskar Brothers, Kirloskar Chillers, Kirloskar Pumps, Kirloskar Motors, Paharpur Cooling Towers and Electronics Corporation of India Ltd, among others, are involved in ITER through domestic agency ITER-India.

Biswanath Sarkar, who is the head of cooling systems engineering division, told IANS that approximately 30 Indian firms are directly and indirectly involved.

This provides direct and indirect employment to thousands of skilled engineers and technicians and un-skilled manpower.

Asked about the benefits Indian industry is reaping from the the ITER project, he said it is a platform that helps industry gain direct experience in key fusion technologies.

By participating in ITER, the members are also preparing their scientific, technological and industrial infrastructure at home.

“Indian companies still have a lot of scope to grow by associating with this fusion reactor,” Sarkar added.

As per the ITER pact, the original sharing of procurement is decided between the seven members, about 45.5 percent for Europe, and 9.1 percent each for China, India, Japan, Korea, Russia and the US.

Each nation’s contribution (90 per cent) will be delivered “in-kind”, meaning that in the place of transferring money, they will be delivering components and systems directly to the ITER Organization.

The remaining 10 per cent of contributions will be transferred “in-cash” for the operational budget.

In effect, by sharing 10 per cent cash, each nation gets access to all data and even to the technologies involved without having to pay royalties on patents.

Nine large components, amounting to almost a tenth of the project, will be fabricated and sourced from India and these are worth over Rs 10,000 crore. About 50 per cent of the components have been supplied to ITER, said officials.

The 3,850-tonne cryostat is crucial to the ITER machine, providing structural support and also acting as a thermos to insulate the tokamak’s magnetic system, at cryogenic temperature, from the warmth of the outside environment.

The 1,250-tonne cryostat base will be the first machine component to be lowered into the assembly pit in March 2020. The upper cylinder is being assembled in L&T’s India facility.

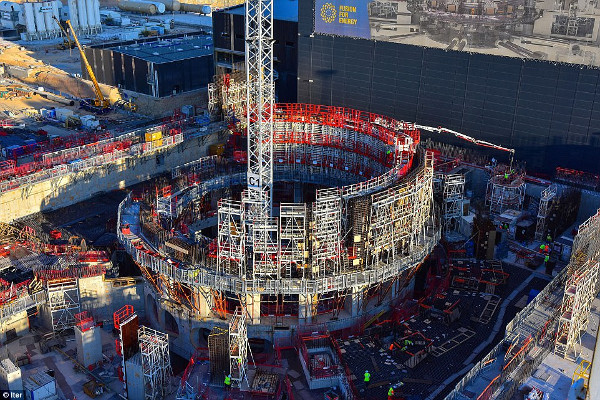

ITER — the way in Latin — is one of the most ambitious energy projects in the world today. It is now 65 per cent ready and the first plasma is scheduled for December 2025 — a key milestone toward full fusion power by 2035.

In total, 35 nations are collaborating to build the world’s largest tokamak – a magnetic fusion device that has been designed to prove the feasibility of fusion as a large scale and carbon-free source of energy based on the same principle that powers the sun and stars.

Over one million components (ten million parts) have been built in ITER member factories around the world delivered to the ITER site. Approximately 2,300 people are working day and night in assembly activities in the facility.

With the installation of the 23,000-tonne tokamak, an experimental machine designed to harness the energy of fusion, the number of employees will go beyond 3,000.

“Not only is ITER a scientific and technological experiment but also an opportunity to learn how to work together and develop project management with other cultures,” ITER site construction Deputy Director Prabhat Kumar told IANS.

The companies involved in ITER are pushing the boundaries of engineering and manufacturing in many fields such as robotics and fabrication on a massive scale with unprecedented cryogenic, electromagnetic, power electronics and vacuum systems.

The first machine component, part of the Chinese-supplied superconducting coil feeder, has been installed in the bio-shield, and the first commissioned system, the US-supplied electrical switch yard, is now in use.

In the assembly hall, both the Korean-supplied 800 tonne sub-sector assembly tools are now installed.

Europe has also handed over the magnet conversion building to the ITER organisation, where electrical components supplied by China, India, Korea, and Russia are undergoing installation.

At home, ITER research and development will enable India, which needs increasing amounts of energy, become a future supplier rather than a buyer of fusion technology.

Source:ET

Image Courtesy: Daily Mail

You may also like

-

India’s Strategic Rise Through Free Trade Agreements: Achievements and Impact (2025–26)

-

Reforming for Growth: How Policy Changes Are Transforming India’s Business Environment

-

India to Build First Riverine Lighthouses on Brahmaputra to Boost Inland Waterway Navigation

-

India Assures Energy Security Amid Rising Tensions in the Middle East

-

GPS Technology Transforms Fishing Livelihoods in Car Nicobar