Jamshedpur, July 31: Nest-In, Tata Steel’s modular construction solutions brand, has launched a revolutionary onion storage solution ‘Agronest’ that is aimed at reducing spoilage of the onions to half of its current level.

This is a first-of-its-kind smart warehouse for onions developed with scientific backing and latest innovations and technology. The lack of scientific storage practices, non-standard designs and poor quality of material used for onion storage leads to over 40% loss of the produce inside the warehouse. With unpredictable weather and climate changes and the recent challenges of transport and movement, farmers face multiple challenges with respect to storage and maintaining a healthy shelf life for their produce. Over the years, farmers have suffered losses in quality and quantity of their produce, as the onion industry lacks proper storage facilities.

P. Anand, Chief, Services & Solutions, Tata Steel, said: “We strongly believe achieving self-reliance and self-sustainability in agriculture is critical to making India atmanirbhar. Inspired by this mission, our expert professionals are developing customised solutions for the agriculture sector. Climate change and environmental conditions affect the shelf-life of the farmers produce and lack of proper storage facilities lead to huge losses. We understood the problem here and our teams crafted a solution that is long-term and practical. We are committed to creating innovative products and solutions for our customers and enable a better tomorrow.”

Given that the agricultural sector supports 70% of India’s population and contributes to 50% of the GDP, the government is rapidly investing in Farmer Producer Organizations (FPOs). Tata Steel’s Innovent team identified this white space in the market to build solutions in agri-infrastructure.

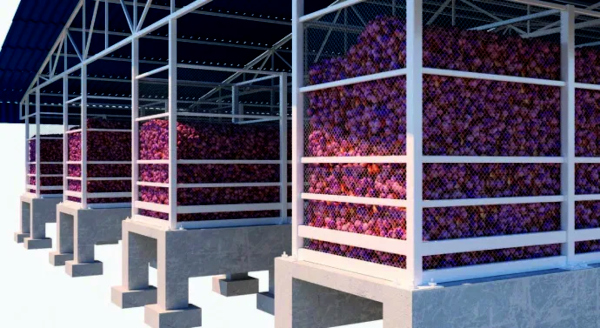

Taking a step forward to achieve this objective and support the backbone of the Indian economy, Tata Steel’s Nest-In and Innovent teams have developed Agronest, a smart warehouse solution with a unique structural design that maximizes air flow, is spacious thus making it conducive for longer and safer storage of onions, and provides a cost-effective environment control to ensure minimal wastage. The warehouse has sensors installed for monitoring temperature, humidity and gas, thereby enabling early detection of spoilage of the produce.

Source: AvenueMail

You may also like

-

India to Build First Riverine Lighthouses on Brahmaputra to Boost Inland Waterway Navigation

-

₹4,400 Crore Push for Tamil Nadu: PM Narendra Modi Unveils Major Infrastructure Projects in Madurai

-

₹3,000 Crore Catalyst: How India’s 11 Industrial Corridors Are Redrawing the Manufacturing Map

-

India’s Space Ecosystem Gets Cyber Shield as SIA-India, CERT-In Release Joint Guidelines

-

NHAI to Develop First of its Kind ‘BeeCorridors’ Along the National Highways