Chenab Bridge, the world’s highest railway bridge, part of the Udhampur-Srinagar-Baramulla rail link project (USBRL), set an important construction milestone today with completion of the steel arch of the iconic Chenab Bridge. This was one of the most difficult part of the bridge over Chenab. This achievement is a major leap towards the completion of the 111 k.m. long winding stretch from Katra to Banihal. It is arguably the biggest civil-engineering challenge faced by any railway project in India in recent history. The 5.6-metre last piece of metal was fitted at the highest point today and joined the two arms of the arch that currently stretch towards each other from both the banks of the river. This completed the shape of the arch that will then loom over the treacherous Chenab, flowing some 359 metres below. After completion of the arch work, removal of the stay cables, filling of the concrete in the arch rib, erection of the steel trestle, launching of the viaduct and track laying work will be taken up.

The completion of the historic Arch work was also seen by Shri Piyush Goyal Minister for Railways, Commerce & Industry and Consumer Affairs, Food & Public Distribution, Shri Suneet Sharma, Chairman & CEO, Railway Board, Shri Ashutosh Gangal, General Manager Northern Railway through video conferencing.

Salient Features of the Arch of the iconic Chenab Bridge:

- Indian Railways is constructing the iconic Arch Bridge on River Chenab as a part of the USBRL project to connect the Kashmir valley to the rest of the nation.

- This bridge is 1315m long.

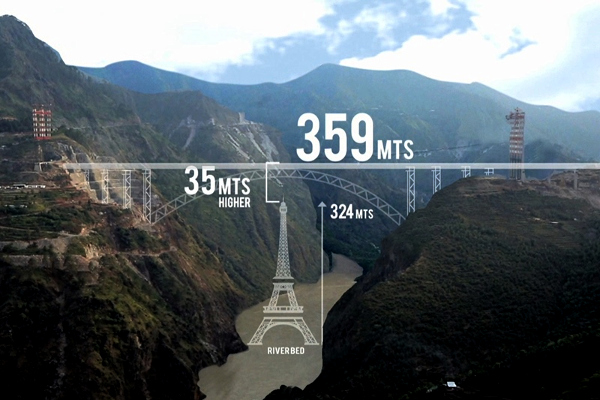

- This is the highest Railway Bridge in the world being 359m above the river bed level.

- It will be 35 meters higher than the iconic Eiffel Tower in Paris (France).

- Construction of Bridge involved fabrication of 28,660 MT steel, 10 Lakh Cum Earthwork, 66,000 Cum Concrete and 26 Km motorable roads.

- Arch consists of steel boxes. Concrete will be filled in boxes of the Arch to improve stability.

- Overall weight of Arch is 10,619 MT.

- Erection of the members of arch by overhead cable cranes done for first time on Indian Railways.

- The most sophisticated ‘Tekla’ software used for structural detailing.

- Structural steel suitable for -10°C to 40°C temperature.

Certain features are tabulated below:

1. Client: Northern Railway

2. Executing Agency: M/s Konkan Railway Corporation Ltd.

3. Cost of Bridge: 1486 Cr.

4. Contractor: M/s Chenab Bridge Project Undertaking [Ultra-AFCONS-VSL(JV)]

5. Total length of bridge: 1.315km

6. Number of spans: 17 nos.

7. Length of Main arch span: 467m (linear); 550m (curvilinear)

8. Design life of the bridge: 120 years

9. Design speed: 100 kmph

10. Total Steel Fabrication: 28660 MT (approx)

11. Design wind speed: 266 kmph

12. Designers:

A. Viaduct & Foundations: M/s WSP (Finland)

B. Arch: M/s Leonhart, Andra and Partners (Germany)

C. Foundation Protection: Indian Institute of Science Bangalore

13. Proof Consultant:

A. Foundation & Foundation Protection: M/s URS, UK

B. Superstructure of Viaduct & Arch: M/s COWI, UK

14. Slope Stability Analysis: (Independent Consultant) M/s ITASCA, USA

15. Slope Stability Analysis: Indian Institute of Technology, Delhi

16. Seismic Analysis: Indian Institute of Technology, Delhi & Roorkee

Unique Features of This Bridge:

- Bridge designed to withstand high wind speed up to 266 Km/Hour.

- Bridge designed for blast load in consultation with DRDO for the first time in India.

- Bridge will remain operational at restricted speed of 30 Km/Hour even after removal of one pier/trestle.

- Bridge designed to bear earthquake forces of highest intensity zone-V in India.

- First time on Indian Railways, Phased Array Ultrasonic Testing machine used for testing of welds.

- First time on Indian Railways, NABL accredited lab established at site for weld testing.

- Approx. 584Km welding done to join the different parts of structure, which is to the tune of distance between Jammu Tawi to New Delhi.

- Height of cable crane’s pylon at Srinagar End is 127m, which is much taller than Qutub Minar of 72m.

- Launching of curved viaduct portion done for first time on Indian Railways using End Launching Method.

- Extensive health monitoring and warning systems planned through state of art instrumentation.

Details about ceremony of Arch Closure:

- Before closure and during launching, arch is being supported by stay cables.

- Closure includes the erection of last 8 segments (4 no. upstream and 4 no. downstream) of Arch.

- The process of arch closure started on 20 February, 2021. Before ceremony for closure of arch, 07 segments were erected in advance.

- At the time of closure of arch, segment no. WT28 was erected. This segment is at kauri end (west end) of the crown.

- Name: WT28 (upstream side top chord segment)

- Size: 5.6 m x 4.0 m x 0.98 m ( L x B x H ); Weight =18.95 MT

After the closure of the Arch, the other activities such as removal of stay cables, filling of concrete arch with self-compacting concrete, erection of trestles, launching of deck over main arch by incremental launching will be undertaken.

Progress of Important activities:

| S.No. | Activities | Scope | Completed |

| 1. | Fabrication | 28,660 MT | 28,595 MT |

| 2. | Overall Erection | 28,660 MT | 16,902 MT |

| 3. | Erection of Arch | 10,619 MT | 10,236 MT |

| 4. | Rock Bolts | 69,343 Rmt | 66,683 Rmt |

| 5. | Shotcrete | 75,061 Sqm | 73,761 sqm |

You may also like

-

India to Build First Riverine Lighthouses on Brahmaputra to Boost Inland Waterway Navigation

-

₹4,400 Crore Push for Tamil Nadu: PM Narendra Modi Unveils Major Infrastructure Projects in Madurai

-

₹3,000 Crore Catalyst: How India’s 11 Industrial Corridors Are Redrawing the Manufacturing Map

-

India’s Space Ecosystem Gets Cyber Shield as SIA-India, CERT-In Release Joint Guidelines

-

NHAI to Develop First of its Kind ‘BeeCorridors’ Along the National Highways