A novel nanostructure developed by scientists can detect oxides of nitrogen at very low concentrations at room temperature, addressing the urgent need for precise air quality monitoring systems in urban and industrial areas.

Gas sensors play a pivotal role in modern technology, facilitating environmental monitoring, industrial safety, and healthcare diagnostics. The field of gas sensors is continuously evolving through innovative research in materials and technology, aiming to enhance key parameters such as sensitivity, selectivity, response and recovery times, stability, and operating temperature. Achieving a sensing device that shows superior performance across these parameters remains a primary objective of current research and development activities in sensor technology, although it poses significant technical challenges. The choice of materials for gas sensors is critical, exerting a profound influence on their operational performance.

In the last few decades, chemiresistive gas sensors, which detect the gas molecules based on variation in materials resistance, using various types of binary metal oxide semiconductors have been extensively studied for detecting different gases. However, most of these sensors commonly lack selectivity for specific gases and face challenges like low sensitivity at ppb levels and the need for high-temperature operation, limiting their practical use.

Addressing the limitations of existing sensing materials, researchers from Centre for Nano and Soft Matter Sciences (CeNS), an autonomous institute of DST have developed a gas sensor based on mixed spinel zinc ferrite (ZnFe2O4) nanostructures. This sensor detects nitrogen oxides (NOx) at ultra-low concentrations of parts-per-billion (ppb) levels, even at room temperature marking a significant breakthrough in gas sensing technology.

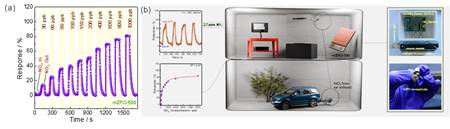

- Dynamic response of the mixed spinel ZnFe2O4 sensor to different concentrations of NO2.

- Schematic illustration of the experimental steps to assess the concentration of NOx molecules from the vehicle emission.

A team of scientists including Mr. Vishnu G Nath and Dr. S. Angappane, deliberately synthesized the mixed spinel ZnFe2O4 structure, where the occupation of Zn and Fe ions within the tetrahedral and octahedral lattice sites deviates from the commonly observed normal spinel configuration.

Advanced techniques such as X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), and Fourier-transform infrared spectroscopy (FTIR) revealed that the distribution of cations in the tetrahedral and octahedral lattice can be effectively adjusted by varying the calcination temperature during nanoparticle synthesis.

Detailed sensing studies underscored the exceptional performance of the sensor based on the mixed spinel ZnFe2O4 structure in detecting NOx molecules under ambient conditions. The sensor exhibited notably high response values (detecting down to 30 ppb), operated at room temperature with rapid response and recovery times, demonstrated superior selectivity, and maintained excellent cyclic stability (approximately 100 cycles) and long-term durability (over 3 months).

The calculated limit of detection (LOD) for NO2 was significantly lower ( around 9 ppb) than the United States Environment Protection Agency (US EPA) recommended limit (53 ppb). Furthermore, the research team validated the practical applicability of the developed sensor by analyzing gas samples collected from vehicle exhaust emissions. They successfully detected trace levels of NOx gas concentrations in the exhaust air samples and accurately quantified the concentration using calibration data derived from known NOx concentrations and corresponding sensor responses. The reduced energy demand for the developed sensor can significantly lower operational costs, paving the way for more affordable and accessible environmental monitoring solutions.

Computational calculations conducted in collaboration with Dr. Subhasmita Ray and Dr. Kartick Tarafder from the Department of Physics, National Institute of Technology Karnataka, validate the experimental findings. These calculations confirm that the formation of the mixed spinel structure leads to higher adsorption energy for NOx molecules compared to the commonly observed normal spinel ZnFe2O4 structure.

Their research published in the Chemical Engineering Journal, not only underscores the significance of mixed spinel ZnFe2O4-based sensors as potential competitors to future high-performance gas sensors but also highlights an effective strategy for leveraging the properties of spinel ferrites through cation distribution modifications. Continued advancements in this area could lead to comprehensive air quality monitoring systems, crucial for mitigating pollution and protecting public health.

Publication link: https://doi.org/10.1016/j.cej.2024.151873

For more details, please contact Dr. S. Angappane (Email: angappane[at]cens[dot]res[dot]in)

You may also like

-

Indian Scientists Rewrite a 50-Year-Old Rule of Bacterial Gene Regulation

-

MeitY Unveils Indigenous 30 kW WBG-Based Integrated Drive System to Power India’s EV Revolution

-

CeNS Researchers Unlock Enhanced Optical Performance with Gold–LC Composite

-

Sarvam AI: Powering a Made-in-India AI Revolution

-

Csir-ampri Designed & Developed Sodar System Facility Inaugurated At IMD