Researchers at the National Institute of Technology, Warangal, have developed a cost-effective and eco-friendly way of producing graphene using one of India and Australia’s most abundant resource – eucalyptus tree.

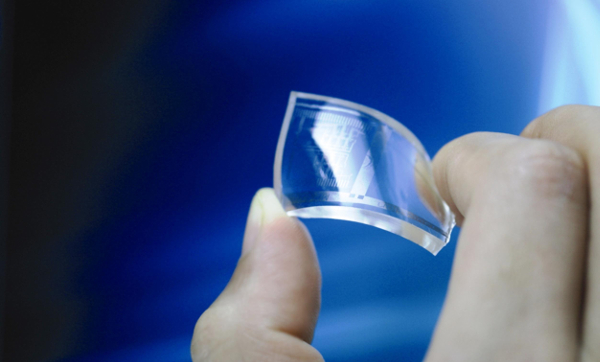

Graphene is the thinnest and strongest material known to mankind so far which is flexible, transparent and conducts heat and electricity 10 times better than copper, making it ideal for anything from flexible nano-electronics to better fuel cells.

A joint research by Indian-Australian researchers, the team comprises Saikumar Manchala, V.S.R.K. Tandava, Vishnu Shanker, the group head, India, and Jampaiah Deshetti and Suresh K. Bhargava, the group head, RMIT University, Australia.

The research was initiated and conducted by Dr. Shanker’s team at the Department of Chemistry and Centre for Advanced Materials, NIT-Warangal and then continued by Prof. Bhargava’s team at the Centre for Advanced Materials and Industrial Chemistry, School of Science, RMIT University, Australia.

The new approach uses eucalyptus bark extract as it is cheaper, sustainable, and highly efficient than current synthesis methodologies of graphene. The study has been published in the ACS journal Sustainable Chemistry and Engineering.

“Eucalyptus bark extract has never been used to synthesise graphene sheets before and we are thrilled to find that it not only works, it is in fact a superior method, both in terms of safety and overall cost,” said Prof. Bhargava.

“Our approach could bring down the cost of making graphene from around $100 per gram to just 50 cents, increasing its availability to industries globally and enabling the development of an array of vital new technologies.”

Graphene’s distinctive features make it a transformative material that could be used in the development of flexible electronics, more powerful computer chips and better solar panels, water filters and bio-sensors.

Dr. Shanker said: “This green chemistry avoids the use of toxic reagents, potentially opening the door for the application of graphene not only for making electronic devices, but biocompatible materials. We love collaborative work with the CAMIC, RMIT. I am confident that together we can make a lot more useful discoveries”.

Chemical reduction is the most common method of synthesising graphene oxide as it allows for the production of graphene at a low cost in bulk quantities. “This method, however, reduces the use of agents that are dangerous to both humans and the environment. When it was tested for the application of a supercapacitor, the e-graphene produced using this method matched the quality and performance characteristics of the traditionally-produced graphene,” said Dr. Shanker.

Prof. Bhargava and Dr. Shanker said the abundance of eucalyptus trees in India and Australia make it a cheap and accessible resource for producing graphene locally.

Source: TH

Image Courtesy: Business Korea

You may also like

-

Indian Scientists Rewrite a 50-Year-Old Rule of Bacterial Gene Regulation

-

MeitY Unveils Indigenous 30 kW WBG-Based Integrated Drive System to Power India’s EV Revolution

-

CeNS Researchers Unlock Enhanced Optical Performance with Gold–LC Composite

-

Sarvam AI: Powering a Made-in-India AI Revolution

-

Csir-ampri Designed & Developed Sodar System Facility Inaugurated At IMD